Many famous Japanese cooks use this knife.

The reason is that it does not rust and its sharpness lasts for a long time.

Also, VG10 production does not require a blacksmith.

A sharpener cuts the steel and hardens it in an electric furnace.

When sharpening, use a diamond whetstone and finish with a natural whetstone

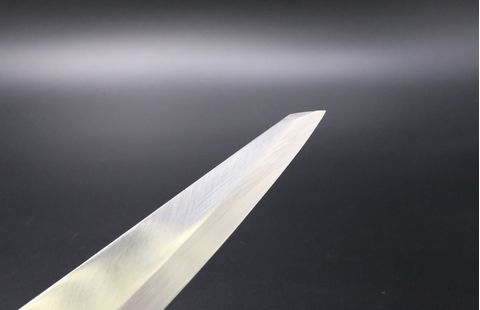

When used, it becomes a razor-like blade.

It is a practical kitchen knife that is fun to use every day.

We want a professional sushi chef to use it.

Material Details

When users choose cutting steels which are suitable for various kinds of knives,

their demands for the performance of cutting steels becomes diverse, but the

indispensable prerequisites of good steel has never changed.

V Gold 10(VG10), a high quality cutting stainless steel, is made from highly-selected

pure iron material and is worked by best technology, thus VG10 has ductility and shows

orkability and forgeability. Besides VG10 is free from corrosion caused by impure substances

and achieves good abrasion resistance. Our V Steel Series boast these excellent features.

VG10 is a highly alloyed stainless cutlery steel, originally developed by Takefu Special Steels

over 60 years ago to make the most of quality raw materials and the alloying effects of various

element to make an all-round, high performance blade steel. The addition of 15% of Cr, 1% of Mo

and 1,5% of Co makes the matrix (substrate) stronger and prevents carbides from dropping out.

By adding V, the structure becomes finer.

Combined Cr, Mo, and V form a lot of hard carbides, so abrasion resistance improves which gives

knives long-term clean cutting, VG10 is rather machinable and easy to grind.

VG10 also has a quadratic effect in high-temperature tempering which makes it ideal to use in cutting

tools which are given surface-coating at up to about 450°C.

Excerpt from steel material manufacturer Takefu Special Steel Co., Ltd. HP

Specification

Description

overseas. Honesuki and Garasuki are different names for different lengths.

Important Notice

*Colour and shape can differ from the photo and actual product due to camera and lighting.

*Also, you may see difference in colour due to the oil applied to protect from rust.

*For handmade products, there may be small scratches. There is no problem in use at all.

*In addition, vintage products may have minor scratches due to long-term storage.

*Wood products may age over time.

Please check the image well before purchasing.

Questions

Review

No posts found